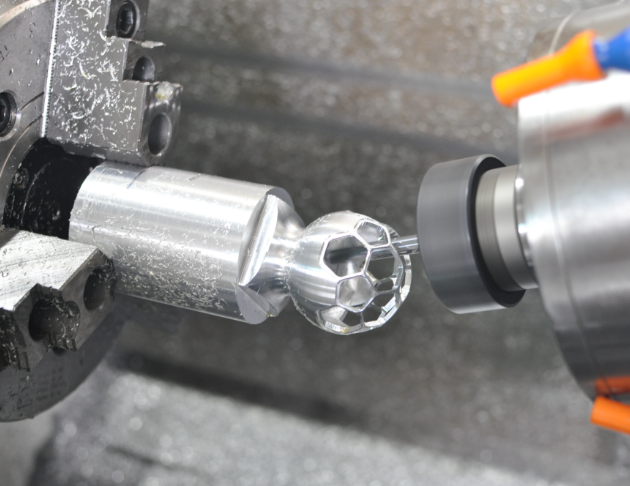

MT-540Mill Turn CenterHigh-Precision Multi-Tasking Machining Solution

Machine Structure & Design Concept

The MT-540 Mill Turn Center is engineered for high-rigidity, high-precision multi-tasking machining. Its advanced structural design integrates turning, milling, and complex multi-axis machining into a single platform, delivering superior productivity and machining accuracy.

The machine base adopts a 45-degree forward slant bed with rear stepped structure, providing excellent chip evacuation, enhanced rigidity, and outstanding thermal stability.

The Y-axis column is designed with a 90-degree orthogonal main column structure, ensuring optimal force transmission and superior cutting stability during heavy-duty milling and turning operations.

All linear axes (X, Y, Z) are equipped with high-rigidity roller-type linear guideways, delivering excellent load capacity, vibration suppression, and long-term precision stability.

Axis Configuration

X, Y, Z Axes

High-rigidity roller linear guideways

Optimized for heavy cutting and high-speed positioning

Excellent dynamic response and positioning accuracy

B Axis

±110° rotary design

Enables full 5-axis simultaneous machining capability

Ideal for complex contour machining and multi-face processing

Key Features & Advantages

45° forward slant bed with rear stepped structure for maximum rigidity

Orthogonal 90° Y-axis column design for superior cutting stability

High-rigidity roller linear guideways on X/Y/Z axes

±110° B-axis rotary for full 5-axis machining capability

Optional multi-function rotary tailstock (0° / 90° / 180°)

Optional sub-spindle for complete machining in one setup

Ideal for aerospace, automotive, medical, and precision components